What to Look for

This report considers typical defects and failures in public water distribution infrastructure which get blamed on old age. In fact, none of these failures was caused by aging infrastructure. In some cases, the infrastructure has not yet failed, but the resulting failures in future years will be just as likely to get blamed on old age.

This report will consider day-one defects which were built into water systems from the very first day of construction, as well as defects and failures which were caused by subsequent damage. We are concerned about the most proximate cause (or causes) of defects and failures in public infrastructure. The causes which are most-responsible for defects and failures should get the most blame. Blaming these defects and failures on old age only encourages the same mistakes and the same deliberate actions which created the defects in the first place.

Water system defects and failures get blamed on old age because that is much easier, and it offends fewer people. With old age, it is nobody’s fault. Our infrastructure was just too old… right? Let’s see.

Case #1 – A Ductile Iron Blowhole Almost Passes the Leakage Test

I got a call from the inspector on a watermain installation contract in Thurston County, WA. The new pipe appeared to have passed the required leakage testing, but the inspector was not sure that the entire reach got tested. The testing was supposedly complete, and the pipe was still holding the 225 PSI test pressure. I recommended that the Contractor should be instructed to release the pressure from the far end of the pipe being tested. However, releasing pressure from the far end had no effect on the pressure gage at the near end. It soon became clear that some of the pipe the Contractor said was being tested had not been tested. The Contractor had closed a valve in the middle and claimed that the entire pipe was being tested. Testing the entire pipe revealed a defective fitting in the previously-isolated section. A newly-installed pipe tee had a pin-hole leak in it. The Contractor preferred not to test the leaking portion because finding and fixing the leak would incur a significant delay.

Photo 1a.- The paint mark on the tee shows the location of a leak in a new ductile iron fitting. The tee has been cleaned off so that it can be re-stocked. Was it patched up and re-installed on your project?

The Contractor had to excavate in several places before locating the leak and removing the defective tee from service. The Contractor was required to replace the tee with one which did not have a hole in it. There is no reason to accept a field-repair for this type of defect. Instead, you should get what you paid for.

There are two important lessons here:

- Brand new pipe and fittings can have defects.

- If you don’t have a method to positively eliminate such defects from your water system, then they are now part your water system.

If you don’t have a qualified, motivated, and honest construction inspector, then congratulations on your new day-one defects. Please don’t blame these types of defects on old age when you find them years from now.

Also consider that defective construction materials which are rejected from one site are routinely patched up and installed on other projects where the inspector is not watching as closely as this one.

Case #2 – Reshaping the Pipe Using Big Rocks

The City of Olympia, WA serves water to the Washington State Capitol Campus. Over the years, the cost of City water had increased to the point where the State wanted to locate the water leakage caused by their “aging infrastructure”.

Instead, they only found leaks which were caused by day-one defects, such as the pipe in Photo 2a which was on the north side of the Temple of Justice near the Greenhouse. The pipe deformation was probably caused during compaction of the trench backfill on day-one, since there were no crossing utilities at the location of the damage. The rate of leakage from this leak alone was estimated to exceed 7000 gallons per day.

Photo 2a. - The granite rocks in this region have a compressive strength exceeding 30,000 PSI, which can easily dent a ductile iron watermain during compaction of the backfill.

Photo 2b. - If big rocks can bend ductile iron pipe like this, then consider the effect on PVC pipe.

The industry-standard contract requirements which keep big rocks away from the pipe are frequently not enforced. The inspector may need to watch every bucket of pipe bedding and trench backfill to prevent this problem from happening. However, this particular day-one defect would have been identified on day-one if the leakage testing had been correctly performed during the original construction. So what happened?

Photo 2c. - The pipe deformation resulted in a 2-inch split in the pipe.

Photo 2d. - It was leaking over 7000 GPD. An expensive cost to Washington State taxpayers from over 30+ years of leakage.

Case #3 – Some Coatings Adhesion Failures

Every water system has some type of plain steel equipment or steel structures in it. Plain steel refers to a type of low-carbon steel similar to ASTM A36 steel, as opposed to a stainless steel material (which corrodes at a much slower rate). The best way to prevent plain steel from rusting is with some type of coating. Once the coatings are compromised, your future ratepayers will be paying for the coatings defects. Pipe coatings can be damaged by incorrect backfilling materials or methods. A reservoir coating can peel off due to incorrect surface preparation.

Photo 3a. - A coating is only as good as the existing coating to which it is applied. A reservoir coating which was applied over earlier re-coats applied by the water district. Ideally, non-conforming repairs would be removed before spending good money on additional coatings.

Photo 3b. - A coating is only as good as the surface which precedes it. A coating peeling off from the exterior of a 12 FT diameter steel tank which was coated in the shop prior to shipment to the site. The paint shop’s own coatings records showed that the underlying primer was not cured prior to the application of subsequent coatings. Since we already had the coating records in our possession, the tank manufacturer was convinced to participate in the cost of repairing this day-one defect.

So let’s review: You have plain steel in your water system. Steel corrodes without quality coatings being applied and maintained in accordance with industry standards. If your coatings are defective, then your steel is corroding. This is going to cost your future ratepayers more than they should have to pay.

Please perform proper surface preparation before coating anything else in your water system. The coating manufacturer must have comprehensive instructions on their website for your specific application, or you should not use that coating.

Case #4 – Epoxy-Coated Steel Couplers

I am not aware of any soils conditions where a buried epoxy-coated plain-steel coupler will have the same service life as the ductile iron (DI) or C900 PVC watermain to which it is connected. All it takes is a single pinhole in the epoxy, and corrosion will start to run under the coating. The pinhole may be a manufacturing defect. The coating can also be easily chipped by a tool or a small rock during assembly or backfilling.

There are too many variables in the science of soils and corrosion to expand one person’s 30 years of experience into every buried steel component. However, I am going to give you the bottom line on buried epoxy-coated steel right here:

- In most soils conditions I have seen, epoxy-coated plain steel components in buried applications tend to last 30-45 years.

- The epoxy coating itself tends to last only 10-20 years unless it is tape-wrapped or otherwise protected.

- The required design life for buried public infrastructure is 50-75 years (TWI Report #1 identifies some exceptions to this).

- Therefore, your buried epoxy-coated plain-steel components are likely to fail before the DI or PVC pipe to which they are attached.

Why would you want that to happen?

Photo 4b. - After installing these epoxy-coated plain steel couplers, the integrity of your entire water system will be dependent on 50-75 years of perfect performance from this epoxy-coated welded steel bracket. That’s not likely to happen.

Case #5 – A Defective Primer Coating

The State of Washington owns this riveted steel water reservoir at the Fort Steilacoom State Historic Park. The reservoir had it’s 100-year anniversary shortly before we prepared the coating contract documents. During the project, the coatings Contractor decided not to install the high-quality industrial primer (or equal) which was specified. He thought it would be better to apply the cheapest shop-primer on the market. The Owner’s representative made the decision to not enforce the Contract (for whatever reason). The results speak for themselves. What are the chances that this grand old reservoir will last another 100 years?

When this water reservoir finally corrodes beyond the point of economic repair, the defects will probably get blamed on aging infrastructure, because that is the easy way out, and the Washington State Taxpayers will never know the difference.

Photo #5. - Cheap shop primer is the same as a high quality industrial coating…right?

Case #6 – The County Road Crew Broke the Existing Watermain

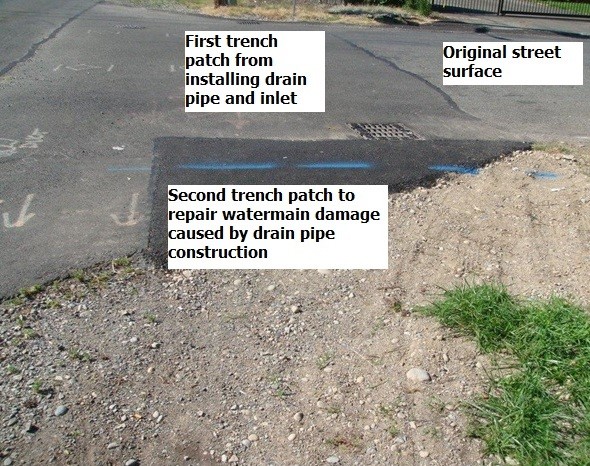

A water system manager in the Puget Sound area of Washington State reviewed her pump records and noticed that the volume of water attributed to leakage had suddenly increased. One possibility was recent construction by the County Road Department, but how could she prove it?

Photo 6a. - Nobody will notice just one little crack in the watermain.

There was a lucky break when she spotted the trench patch in Photo 6b. She could hear and see the water flowing inside the nearby drain inlet. The date of the increased leakage matched the time of the County’s construction.

Photo 6b. - Trench patches tell the story.

Without the recent asphalt patch to tell the story, this crack would look just like aging infrastructure. The County participated in the cost of watermain repairs.

If the earth is excavated away from only one side of a buried structure, then that structure will deflect towards the open excavation. Maybe this will only be a very small amount. A small amount is all it takes to crack some watermains. Sometimes an equal amount of soil can be excavated on each side to even out the forces, and sometimes that is not advisable at all. Use your own judgement, based on your policies and training.

Everything Else

I have seen hundreds of similar cases but I don’t have photos to go with most of them. After a 30-year career, my files are full of these.

There seems to be a low correlation between pipe age and pipe condition. The majority of water system failures that I have seen were actually caused by defects which were present in the failed water system components from the day they were installed, or they were caused by subsequent damage. I suppose that someday the infrastructure will be so old that this will no longer be true, but it is true right now.

Whenever infrastructure defects are mis-categorized, the most proximate cause of the failure will not be correctly identified; the wrong conclusions will be reached, and day-one defects will continue to be installed in brand new infrastructure. In addition, more public infrastructure is getting damaged right now as you are reading this. When will the insanity stop?

For a PDF of this report, click here.